Repurposing and recycling buildings and plant is an approach which more clients should consider if they want to increase their cold store capacity quickly, without hitting their bank accounts too heavily and removing the environmental impact of new build.

This was an avenue our client wanted to pursue with an existing distribution depot that contained cold, chilled, and ambient storage areas. The project involved expanding the cold storage area into the other sections of the building which had previously been chilled and ambient.

Stonegrove’s team came up with a unique design to keep costs as low as possible while providing an extremely efficient industrial refrigeration solution. In fact, the solution was over 30% more cost effective for the client than building a new cold store.

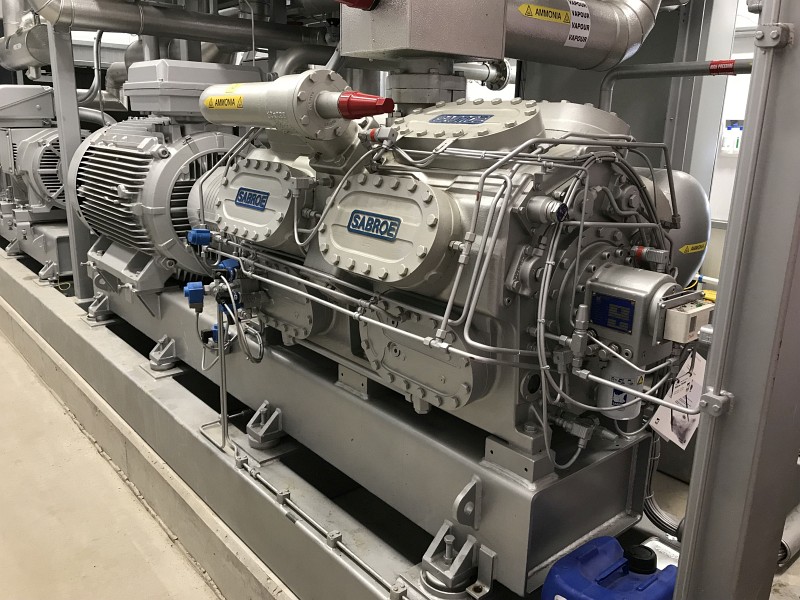

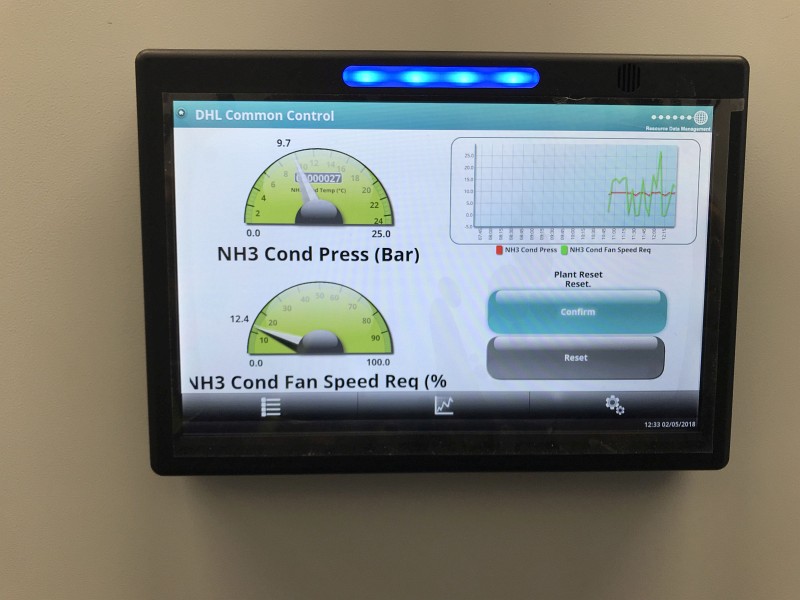

The team managed to repurpose a building for its client predominantly by reusing existing equipment already on site. For example, we re-used four coolers and condenser coolers, and two existing GEA Grasso compressor packs (already 16 years old). Even a set of existing booster fans were put to good use in the roof void, to aid circulation. All the third-party controls (Grasso and IGD leak detection) were integrated within an RDM control system.