When one of the UK's leading on-line retailers chose to build a major distribution centre in the South East of England, Stonegrove were selected to install the refrigeration plant.

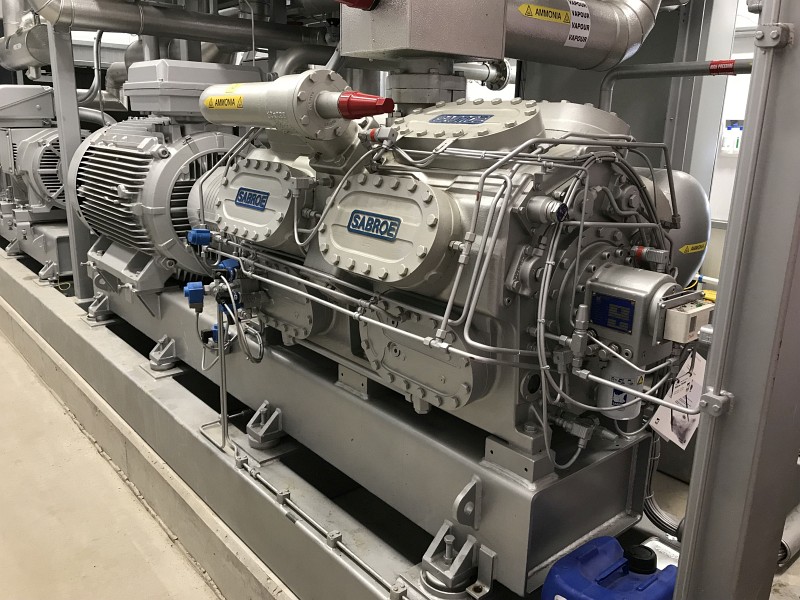

Stonegrove installed a 2 Stage Industrial Ammonia plant with an LT ammonia pump vessel and a set of HT plate heat exchangers mounted under a specially designed surge drum which incorporates a bubble type intercooler. Installed on a separate skid are 5-off inverter driven cold glycol pumps with 55kw motors.

The installation was designed to be energy efficient using the highly efficient GEA Grasso V Series Reciprocating compressors complete with DC motors and matching inverters. There are 6 Grasso V1800 on the chill plant (5 run, and 1 standby to both chill and frozen), and 1 Grasso V1100 acting solely for the frozen.

The defrost system is designed to operate via a series of plate heat exchangers, which exchange waste from the ammonia discharge line to the warm defrost circuit. The heat for the underfloor heater mat is generated in a similar way with its own plate heat exchanger - likewise in the discharge of the ammonia pipework.

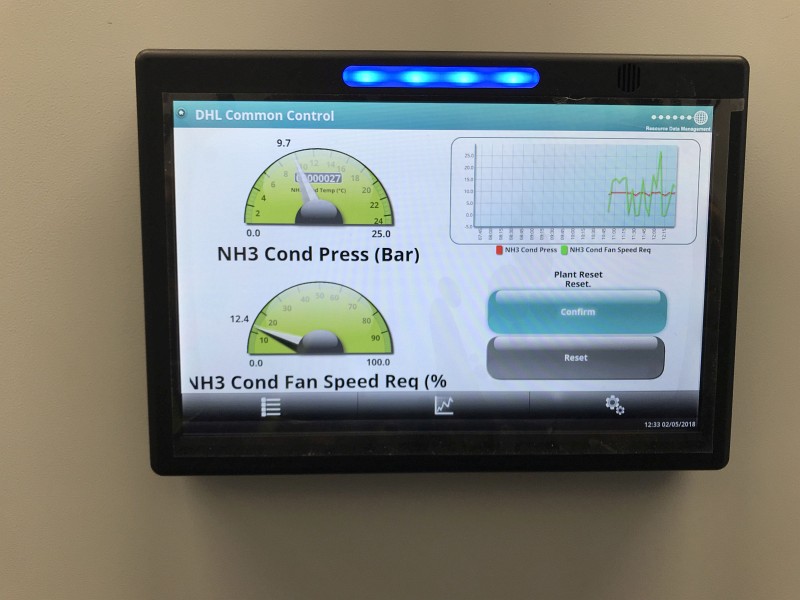

The ammonia detection system and the electrical and control systems ware custom built.

Throughout the chilled and frozen areas there are 100 evaporators with with duties ranging from 80kw down to 4kw each. We installed in excess of 8 miles of pipework, which included 2 miles of condensate drainage.

Other major plant installed on site were 2-off Evapco Condensers and 1-off 4T Liquid Receiver.

The total chill duty was approximately 5MW, with a freezer duty of approximately 500KW.