With continued growth in their business, our client needed to create further chilled storage and an additional chilled picking area to meet demand.

The rooms were installed within a live production area, so we had to work with limited access which included both during normal working hours and out of hours. This ensured minimal impact for the customer and allowed them to continue with the smooth running of their business.

The New Chill Room is 5kW duty 0c air on ET-10c/+35c. There is a single Searle draw through evaporator with electric defrost and a Danfoss Condenser. The system is running on R449a.

The Chilled Pricking Area is 5kW CU and 15kW draw through evaporator (2no Searle coolers) with electric defrost. Air on 0c, ET -10c/+35c. The Condenser is also a Danfoss unit with the system running on R449a.

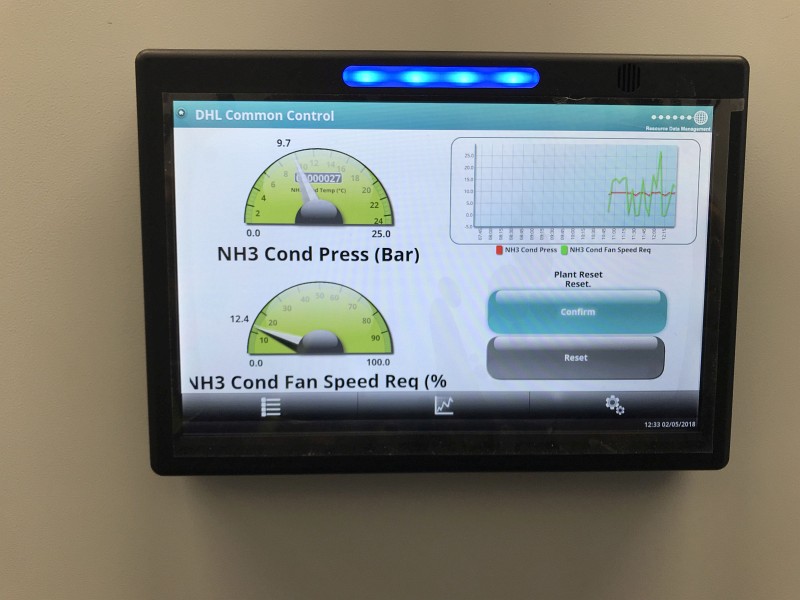

Both room control panels have LED display/ controls for room temperature with RDM control.