When a Tyfoxit chiller plate heat exchanger failed, Stonegrove were called in to fix the issue.

We found secondary fluid had passed into the primary. In order to sort out the issue the ammonia in the chiller needed to be decanted. Polar Pumps recovered and disposed of the contaminated ammonia.

During the process of isloating the secondary fluid circuit we found the old valves would not seal. Because of this we had to install a cold tap on both legs feeding the exchanger. As part of the plate repair works we decided to install two branch tees to allow the install of a temporary chiller if required.

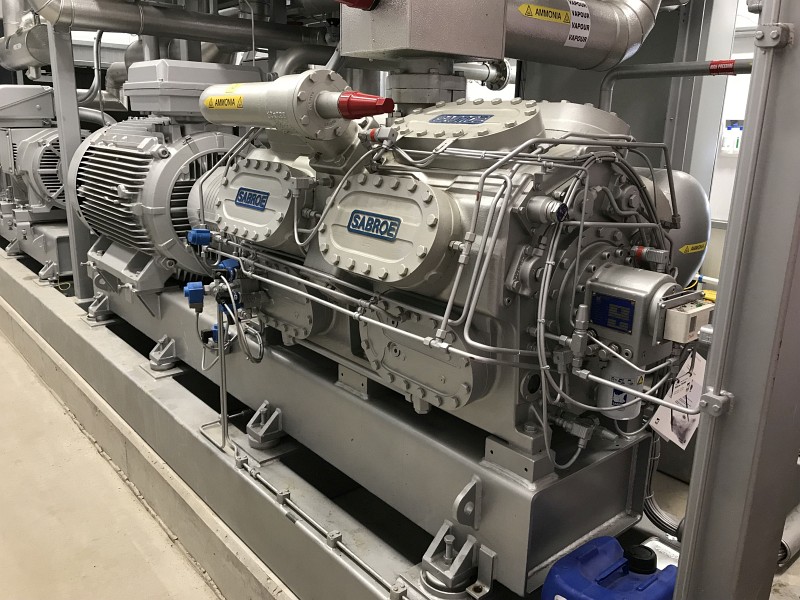

The compressor was flushed with over 400ltrs of oil until clear we were seeing clear oil coming through. The system was triple vacced we replaced several main component O rings.

To help with future maintenance we installed an isolation valve which will help to improve serviceability of the ammonia circuit feeding the plates.

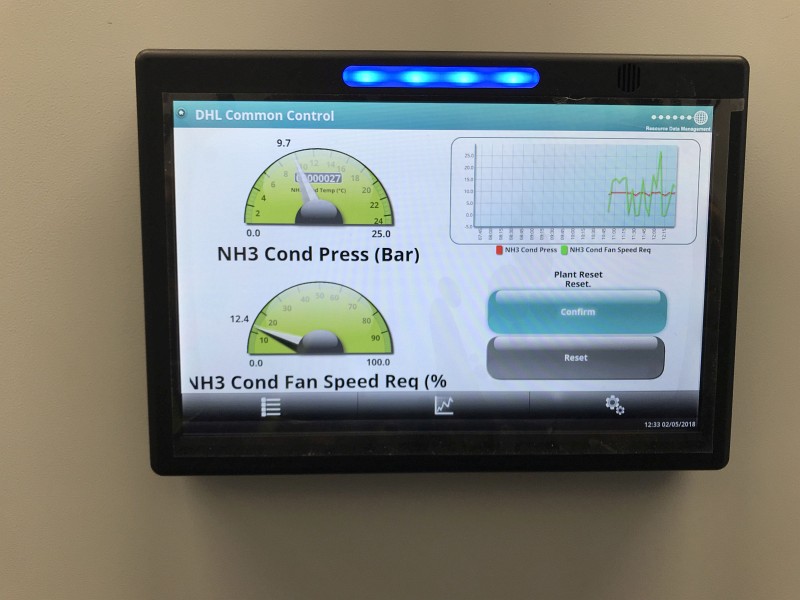

On completion of the works the plant ran up perfectly, and has been in the lead position for the past three months with no issues. In fact due to the plates being clean, we noticed a marked improvement on efficiency at higher suction pressures etc.

The entirety of this project was carried out with no effect on the operating conditions of the factory.