When a leading 3PL company needed a multi-temperature facility for a new client, they selected Stonegrove to supply and install the refrigeration equipment.

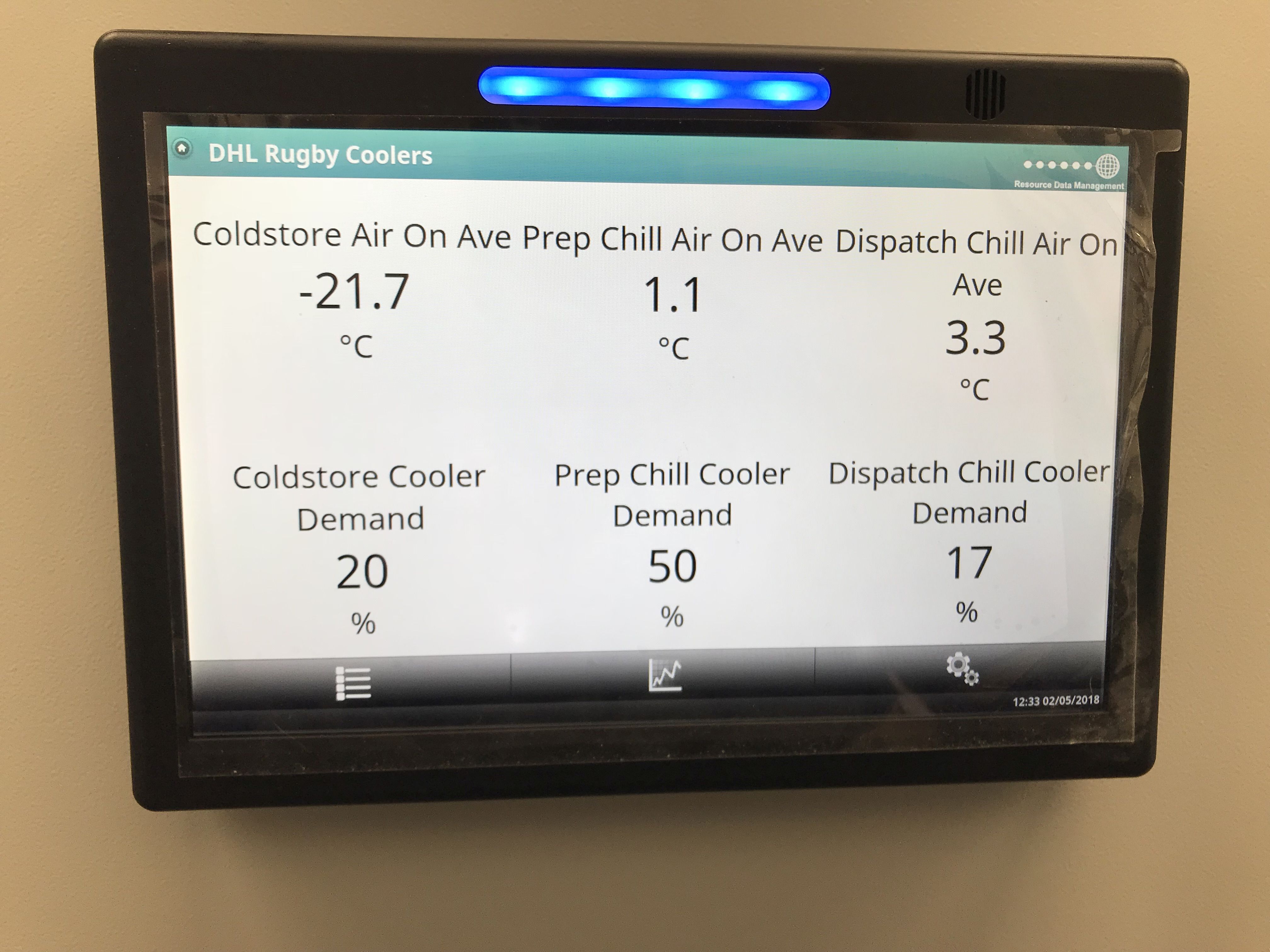

We selected a packaged ammonia glycol chiller to supply the chilled areas and an ammonia/CO2 system for the freezer cold store. The freezer cold store is designed to operate at –25C and the chilled areas +3C. The freezer glycol heater mat was supplied with warm glycol via the discharge gas. Both the high and low temperature systems are very efficient and economical to operate.

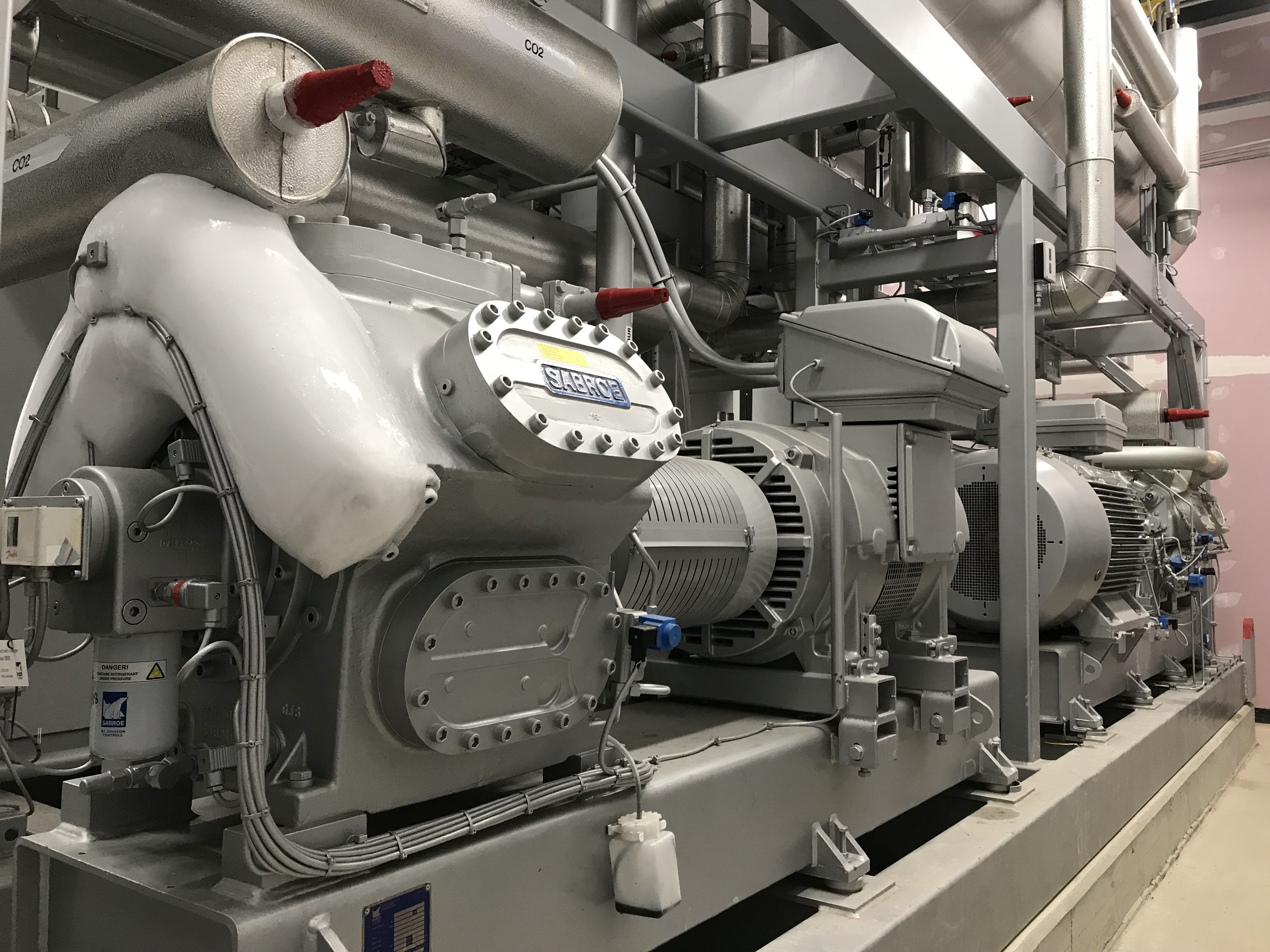

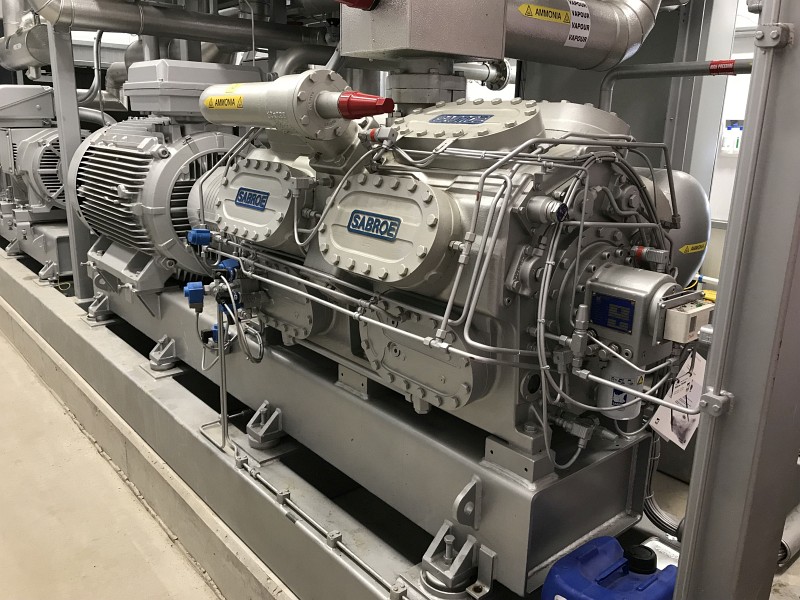

The Sabroe packaged ammonia glycol unit has a total cooling capacity of 585.9kW. The unit was factory tested and delivered complete to site with external cold glycol loop pumps.

The Sabroe ammonia/CO2 system has a high stage compressor with a cooling capacity of 822.2kW and a low stage compressor with a cooling capacity of 668.1kW. Choosing this option has removed all ammonia from inside the factory as the evaporators were supplied with pumped CO2. The unit was factory tested and delivered complete on a skid, there is also a seperate Alfa Laval air-cooled condenser with a 1016.9kW capacity.

All coolers are Alfa Laval with 6no pumped CO2 evaporators in the freezer and 8no glycol evaporators in the chilled areas.

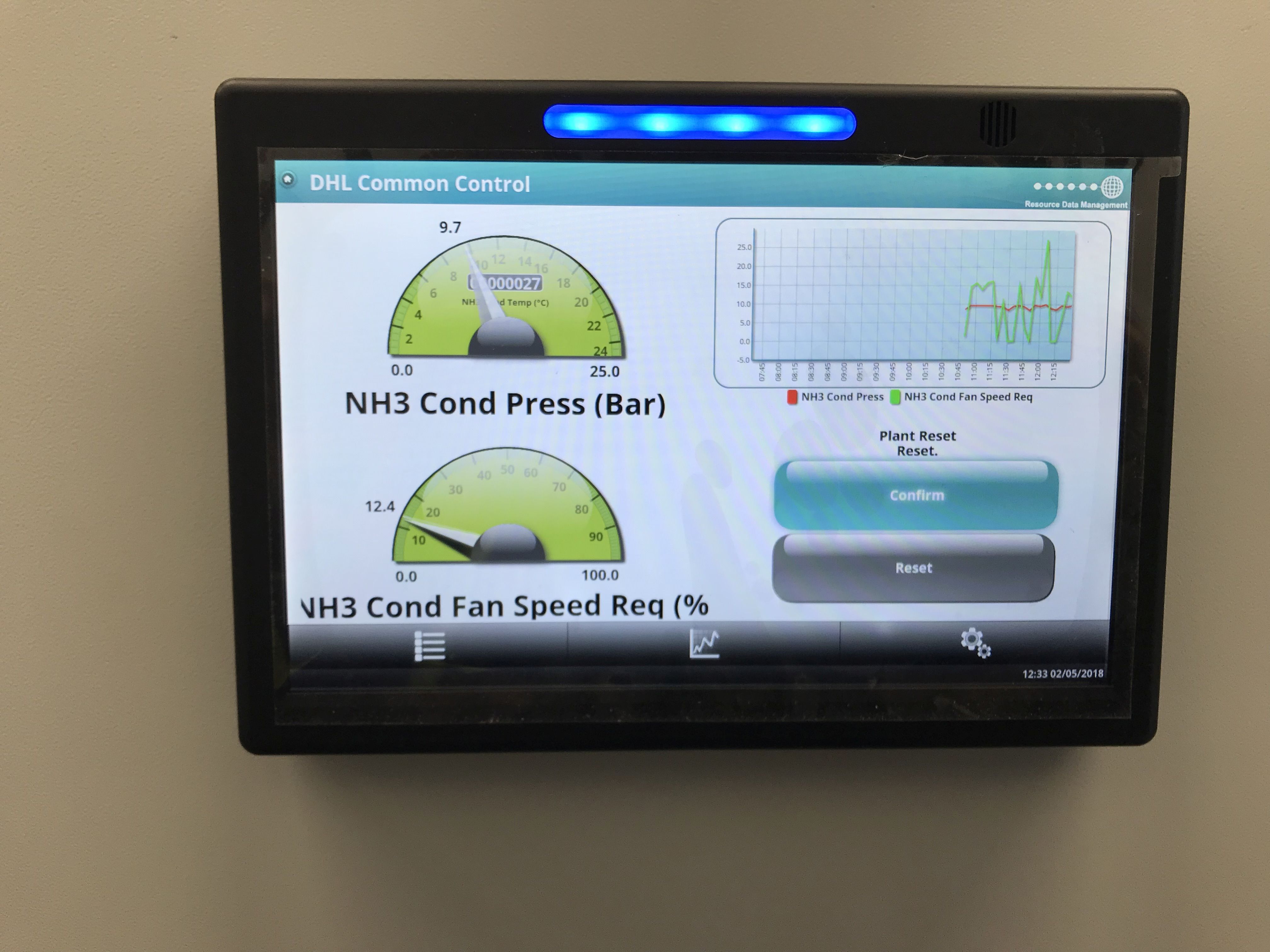

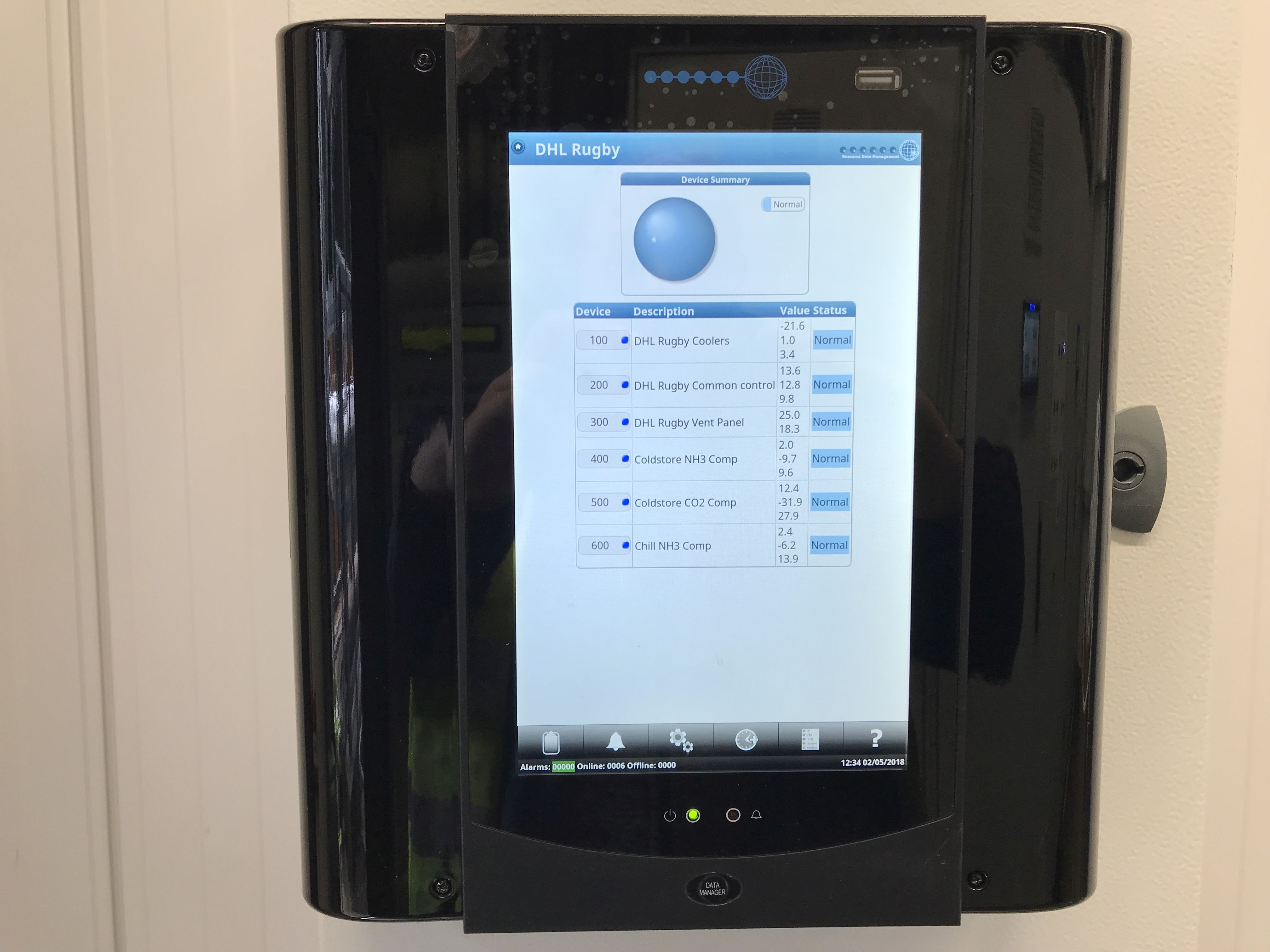

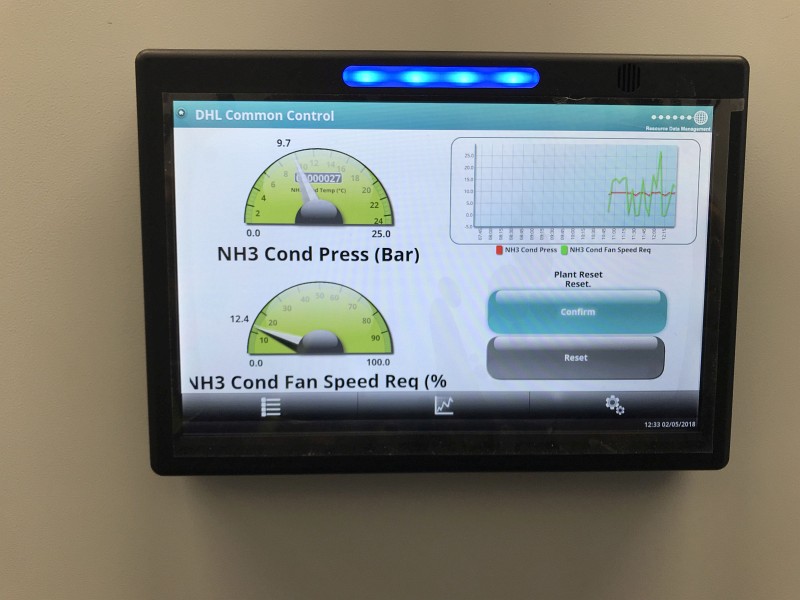

Stonegrove also Supplied and installed an integrated monitoring package (RDM), giving a running status of the equipment, pressures and operating conditions. This covers trends and graphs of temperatures, records of faults, dial out on faults and a dial in facility to interrogate the system if required. We also allowed for wireless independent temperature monitoring via a process parameters OVA system.

The project had a very tight programme, so with this being the first time Stonegrove had worked for the customer we were very pleased to complete ahead of schedule, which helped the other contractors and ultimately the client.