When our client required additional chilled capacity, they asked Stonegrove to re-instate a chilled chamber at one of their sites.

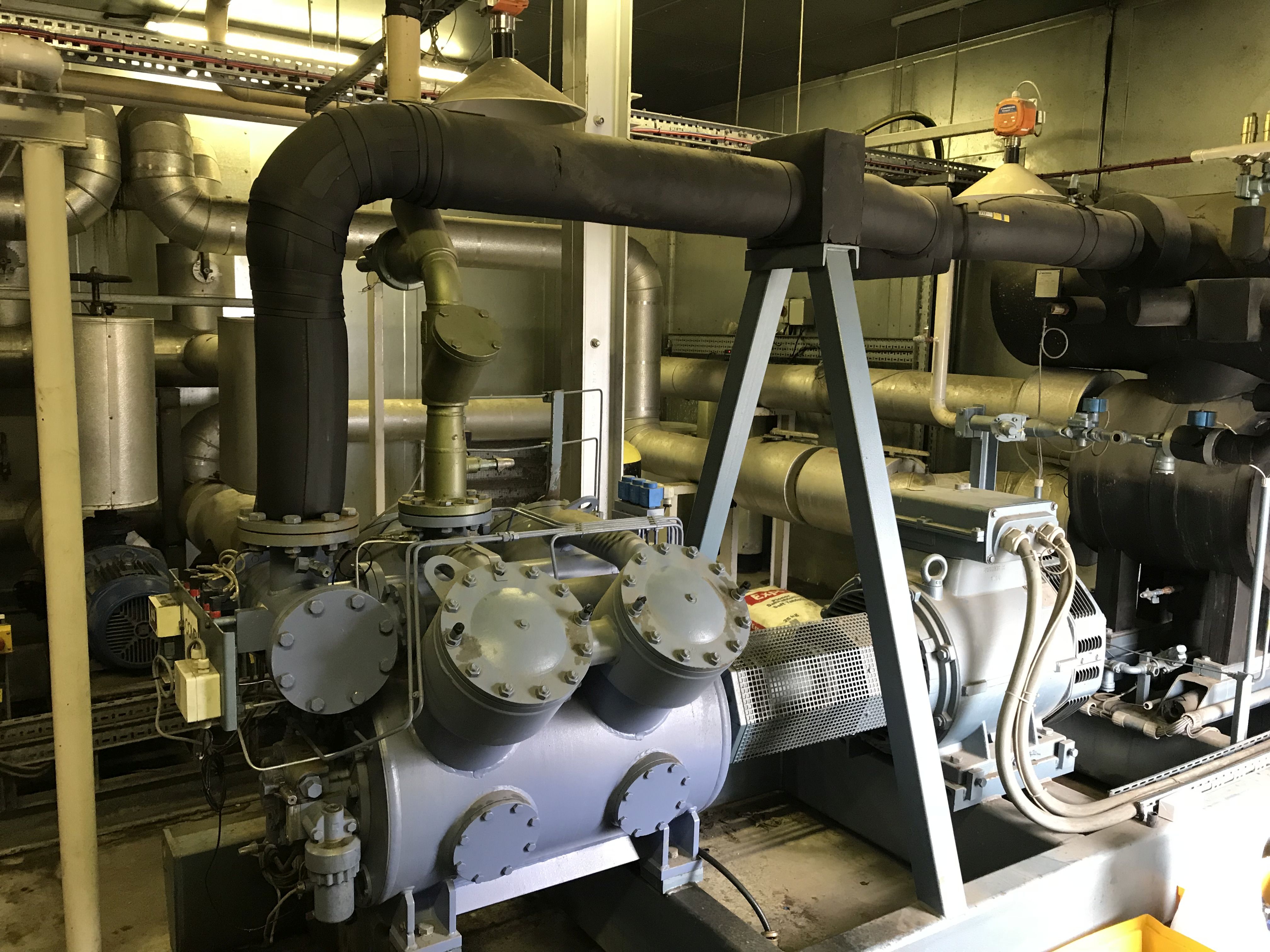

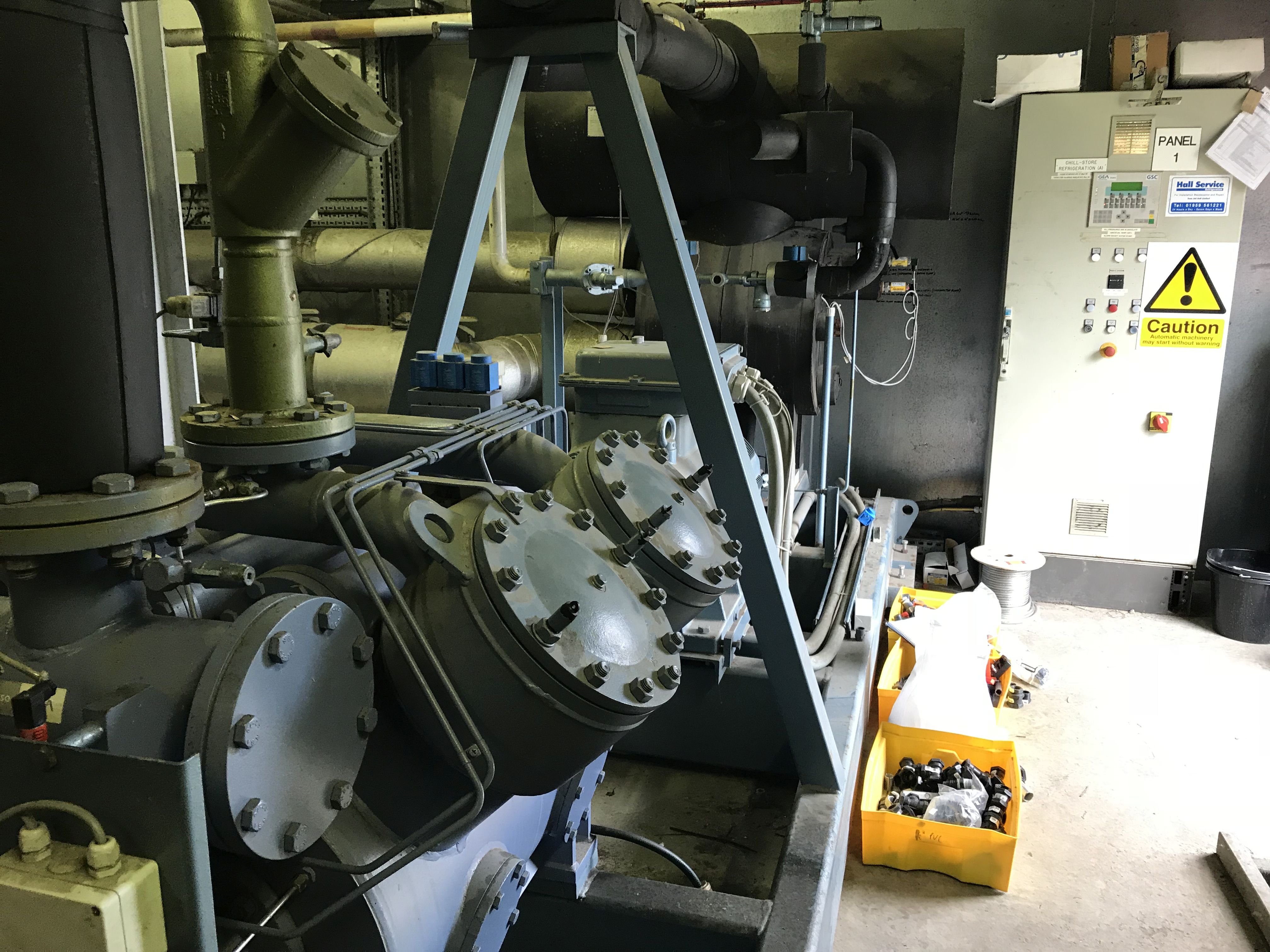

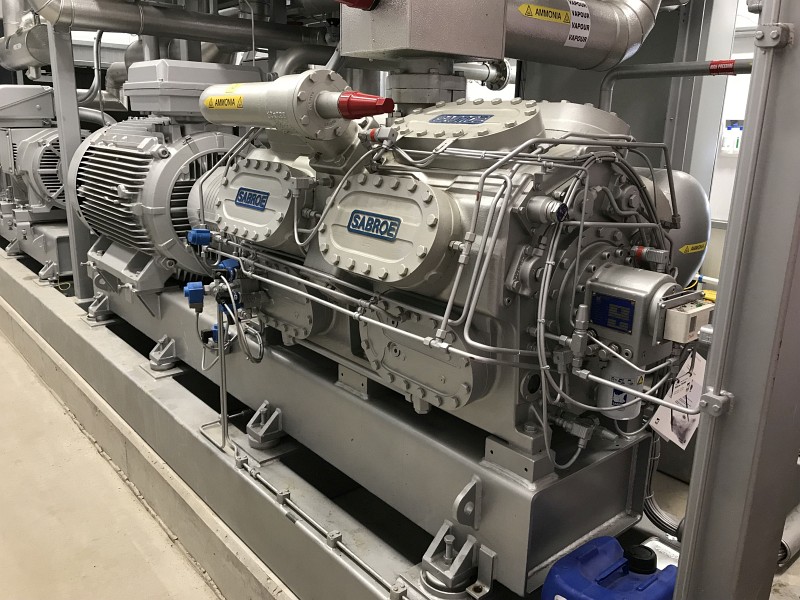

The plant room houses 2 ammonia glycol compressor packs, with a water cooled condenser sited to the rear. The refrigeration equipment had been dorment for a number of years, so we initailly needed to pressure test to make sure the system held pressure. A number of items needed replacing including O rings and seals along with a motor for the glycol pump.

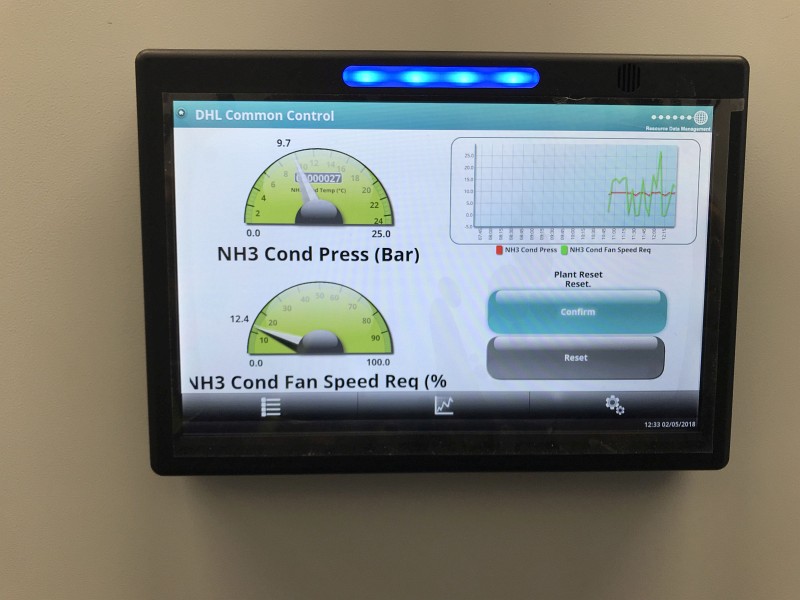

After the repairs were carried out and the system was pressure tested again, the ammonia charge was added and the glycol topped up. Both plant 1 and plant 2 were run to check for further issues, of which there were a number. These included (but were not limited to) the PLC, valves, filters & level switches. Once these further repairs had been made and the refrigeration systems were running correctly, the chamber was brought down to temperture.

Alongside the refrigeration plant repairs, Stonegrove were also tasked with organising repairs to the Water Treatment System. This included a cooling tower controller, pumps, solid dissolver units, new dosing system and a water metre. We also arranged for the deep cleaning of 8no coolers sited within the chill store.