Our client needed to build a new chiller for the storage of beer.

The new store needed to maintain a room temperature of +10 deg C with instructions to future proof the install by using natural refrigerants, and no hazardous substances within the building.

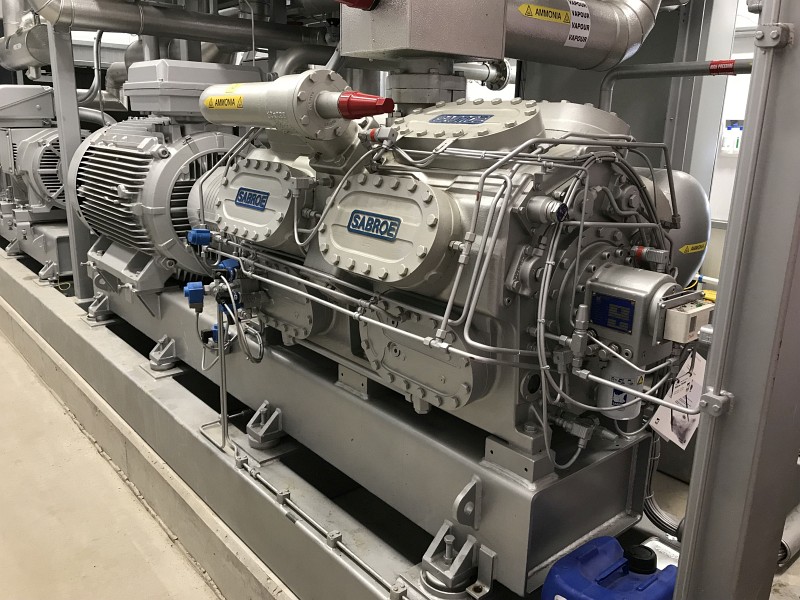

To achieve this we chose Propane as the primary refrigerant and Glycol within the store. The chiller is from TechnaFreddo with two circuits, a split air cooled condenser and inverter drives on the piston compressors. All glycol pipework is thin wall (2mm thick) 304 stainless steel with foil face PIR insulation inside the building and Stainless steel cladding outside.

The pressurisation unit along with the expansion tank is housed in a GRP enclosure adjacent to the chiller.

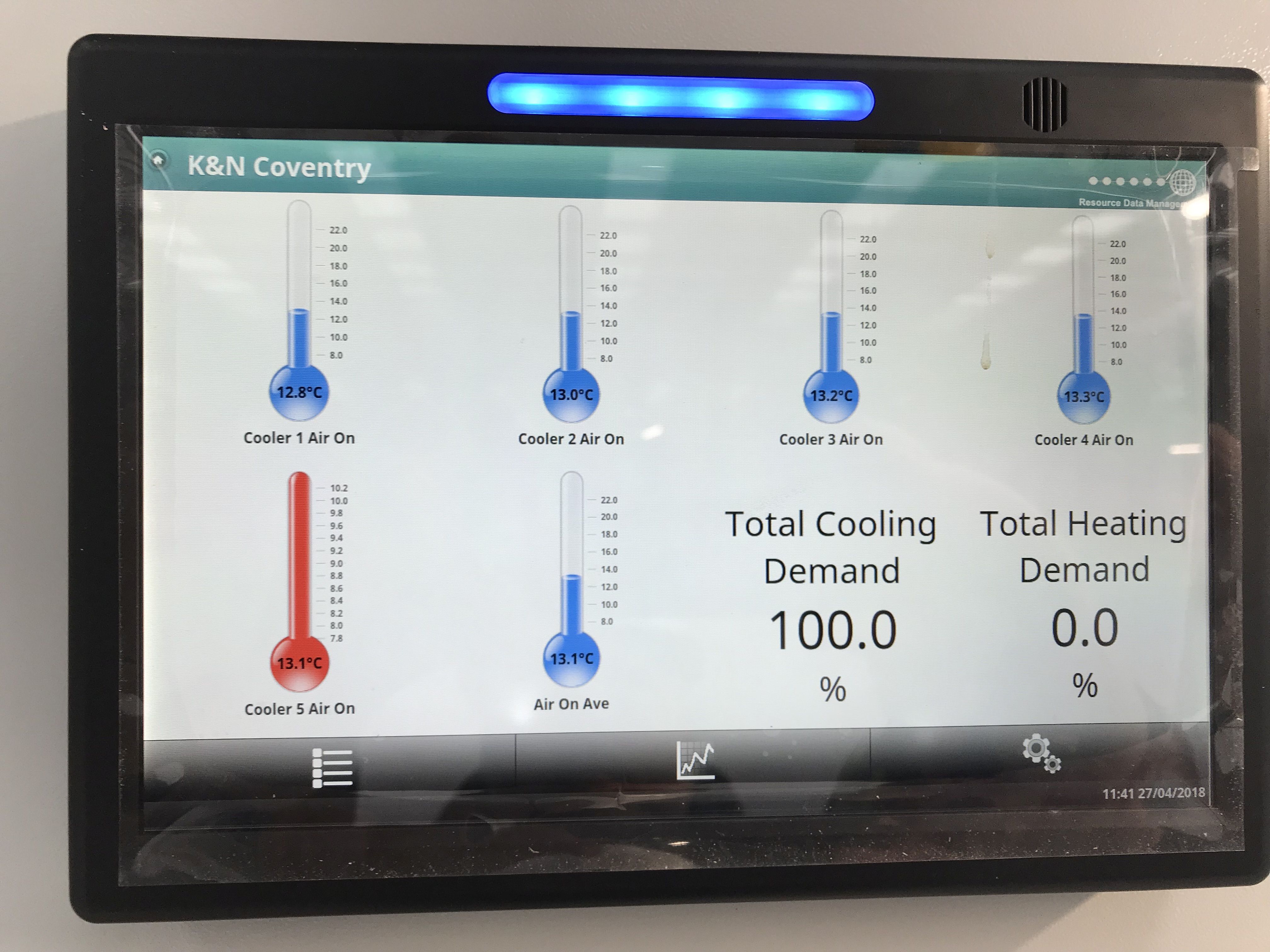

As the room has to maintain 10 degrees, two of the five evaporators are fitted with heater banks to increase the room temperature during low ambient conditions.