Due to continued growth, a leading food service company needed to build a new southern distribution centre. Stonegrove were selected to install a new refrigeration system as part of the build.

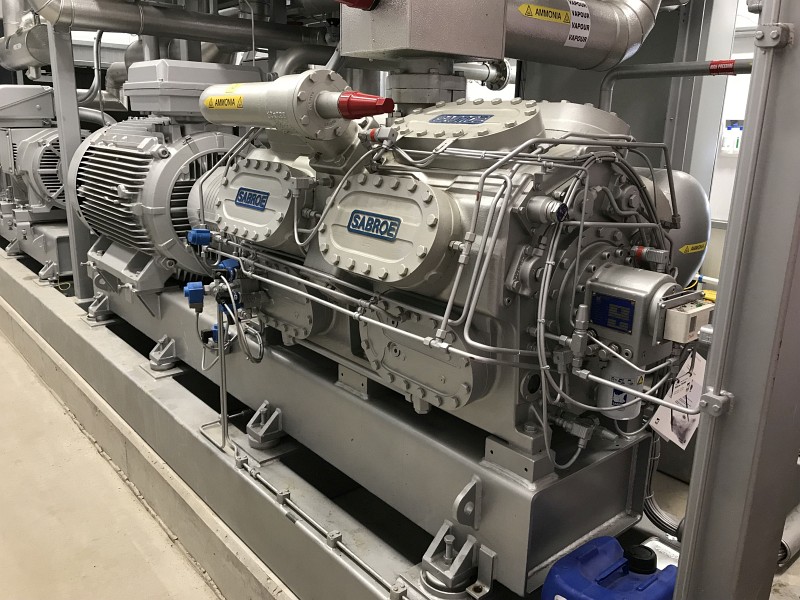

The system installed is a multi-temperature pumped ammonia system. With the low temperature cold store capable of running at -25, the chill store at +2 and the Marshalling area at +4. The plant room has 3 Grasso inverter driven V1100 compressors configured as one high side, one low side and a swing machine. The underfloor heating is achieved using pumped glycol heated from a shell and tube exchanger on the ammonia discharge line, and controlled on the glycol return temperature.

All 10 evaporators (4 cold store, 4 marshalling and 2 chill) are Coolers and Condensers ceiling mounted draw through design.

There are two surge drums complete with pumps, one for the high temperature stage fed from the condenser via a Whitt high side float and the low side fed via a Hanson modulating valve. The high temperature drum also act as an intercooler for the low stage ammonia discharge.

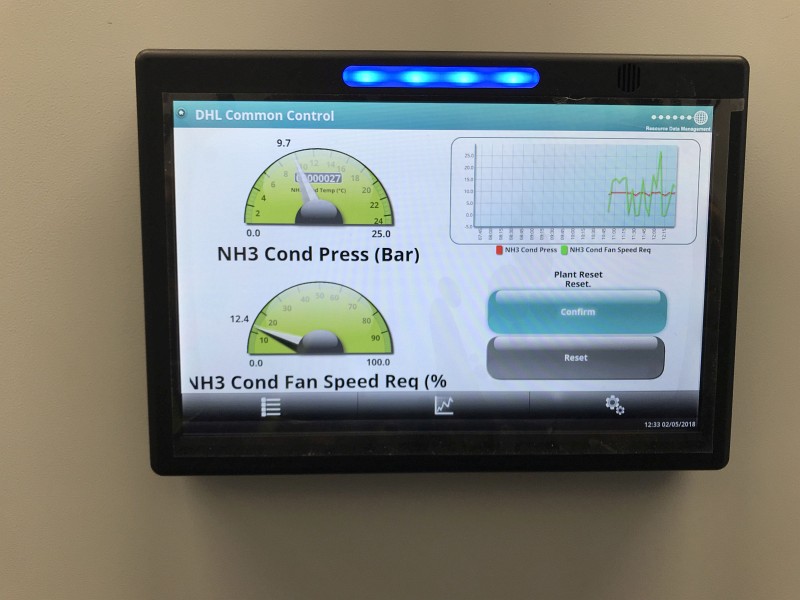

Condensing is taken care of by a BAC evaporative condenser complete with water treatment, access ladder, gantry and inverter driven fan.

A Hansen multi point purger has been installed to take care of any non condensable gas that may accumulate in the future.