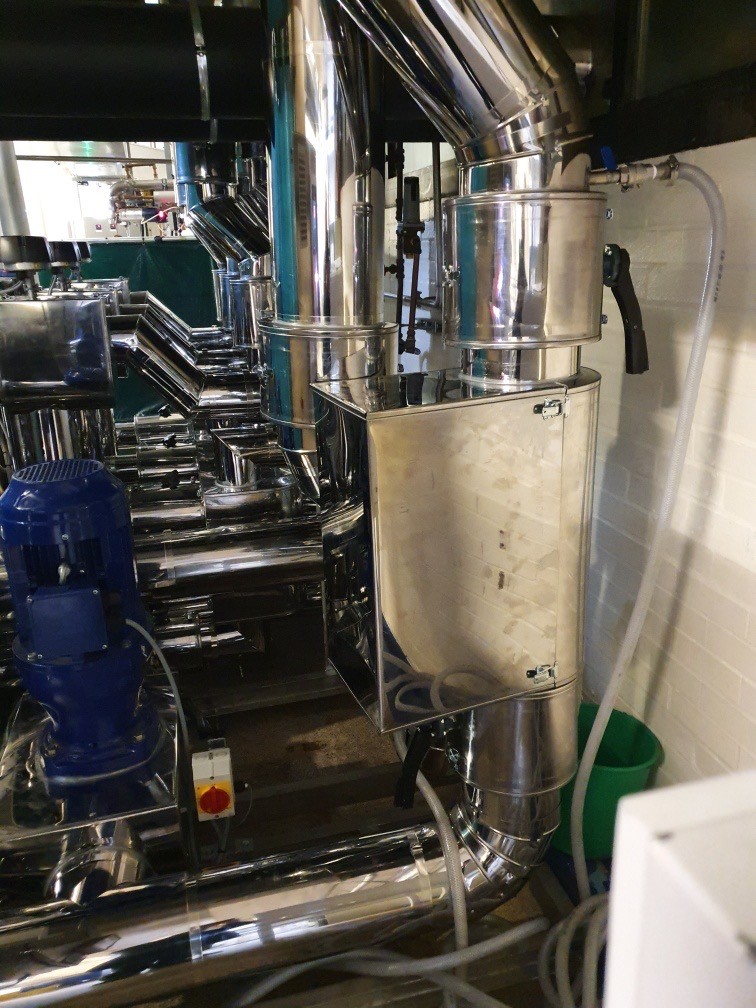

Our Clients bakery was designed to run on 3no chilled water plate heat exchangers, using a main factory cold glycol loop providing a cooling supply to many production cooling tunnels.

Over the years two of the old units had fouled up and blocked leaving only one functioning correctly. Our customer had a 'temporary' hire plate in place to help support the cooling load, but at a high weekly cost. If the final plate failed then the bakery would lose half of its production.

As the cooling lines run 24 hours per day, 7 days a week, the only available planned shut downs are at Christmas for three days and Easter for four days. To prevent any impact on production the works had to take place over the Easter weekend.

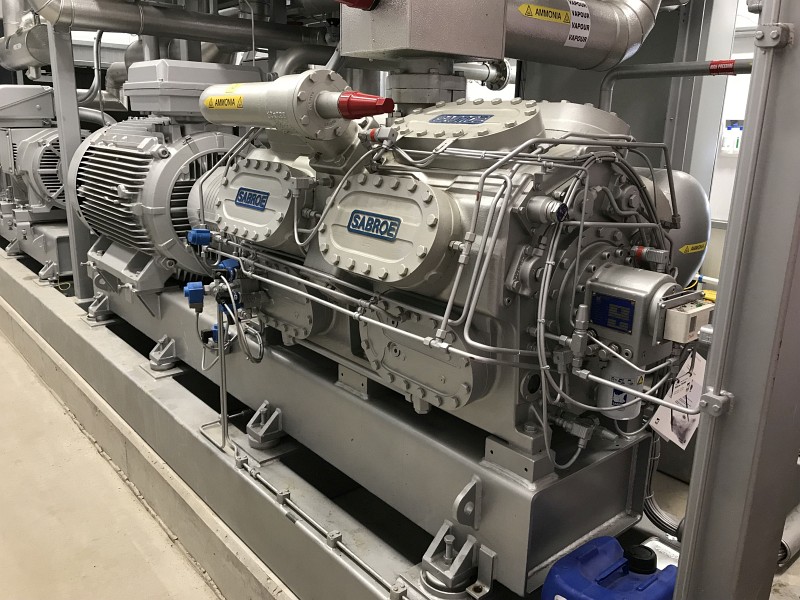

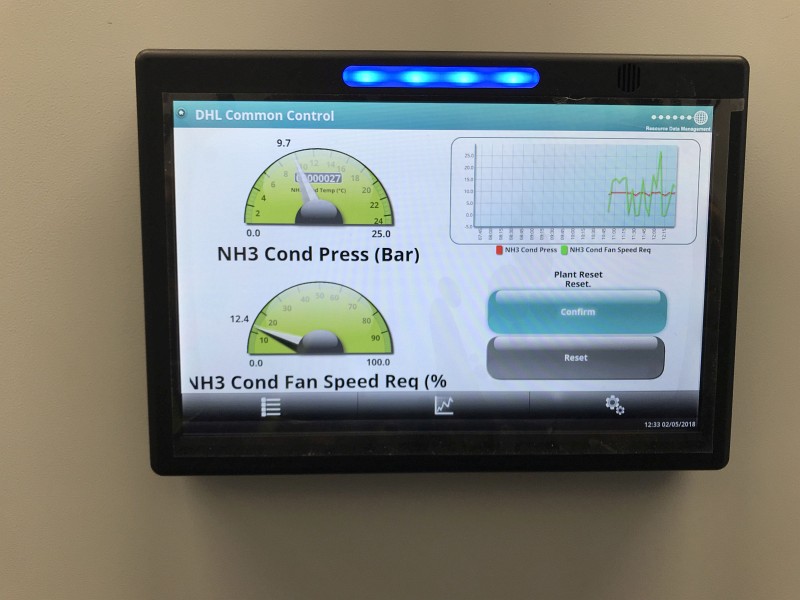

Stonegrove had to design (we had to calculate without any information on the old lines which are over 30 years old) and pre-build the new 3 plate pack and pump skid, to make the change over. We also supplied and installed an RDM system control - programmed in house.

The entire change over took place successfully, within the limited time frame. The Lines are now colder than they have been for 30 years - with a signifcantly increased throughput, creating spare cooling capacity. Another happy customer!