Due to increased demand and continued growth of one of our clients, they needed to expand their production capability. A decision was made to move the suite of offices upstairs and turn the area into a Cheese Prep Room and Cheese Holding Chiller.

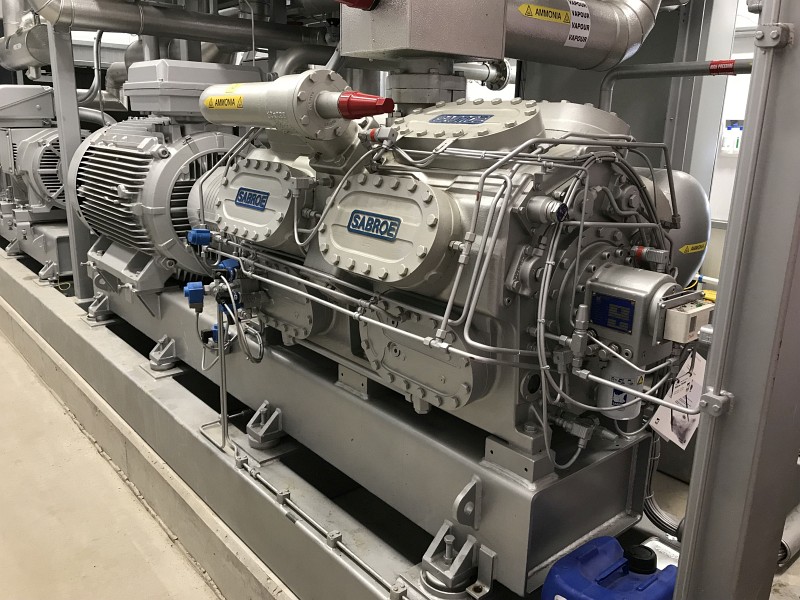

As part of on-going factory refurbishments, the refrigeration plant for the Cheese Holding Chiller was relocated from another part of the facility. High Care Production had previously been extended by de-comissionig and removing an existing chill store. The Pipework from chill store was then extended to the new location and the cooler was re-installed and comissioned.

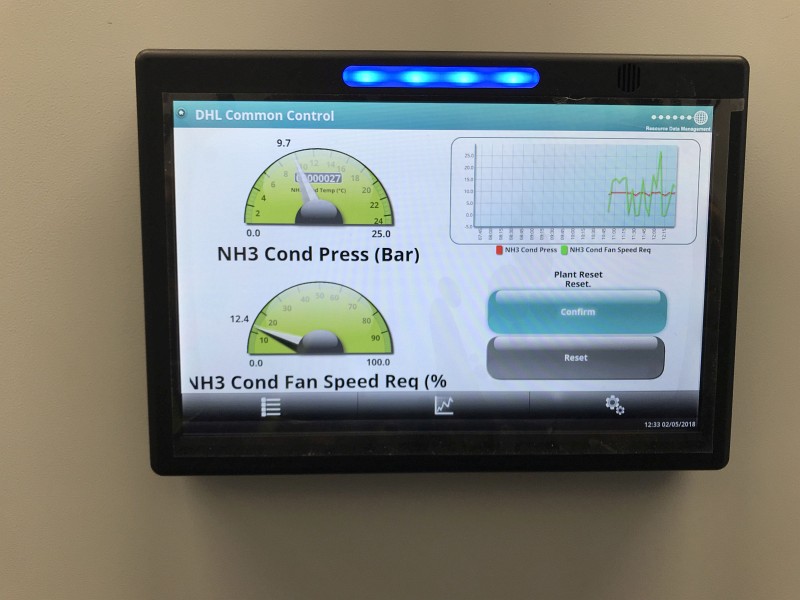

The Cheese Prep Room required new refrigeration plant. Stonegrove installed a Searle Cooler and Danfoss Condenser, and connected the plant to the existing RDM Controller.

Stonegrove needed to work closely with the insulated panel construction company as the installation was time critical and directly impacted on production. We completed and were able to hand the areas over within the time scales requested.